Oxygen is an essential substrate in aerobic cultures, directly influencing cell growth, productivity, and metabolic activity. However, due to its limited solubility in aqueous solutions, a continuous and efficient oxygen supply is vital to maintain optimal culture performance. This makes it necessary to understand and control the maximum oxygen transfer capacity (OTRmax) within a bioreactor or shaking system.

What is OTRmax?

OTRmax (Maximum Oxygen Transfer Rate) refers to the highest possible rate at which oxygen can transfer from the gas phase to the liquid phase within a given system—typically a shake flask or bioreactor. It is usually expressed as milligrams or millimoles of oxygen per liter per hour (e.g., mg/L/h or mmol/L/h).

Once gaseous oxygen dissolves into the culture medium, it becomes available for microbial or cellular respiration. The rate at which cells consume this dissolved oxygen is called the Oxygen Uptake Rate (OUR). If the OUR exceeds the OTRmax, the culture enters an oxygen-limited state, where oxygen availability becomes a bottleneck for growth and metabolism. This phenomenon can negatively impact productivity and cell viability.

Why is OTRmax Important?

Maintaining an OTRmax that exceeds the culture’s oxygen demand is critical for successful process development in:

Pharmaceutical production

Biotechnology applications

Food and fermentation research

Academic and industrial R&D

Understanding your system’s OTRmax allows you to:

Predict and avoid oxygen limitation

Optimize shaking or aeration conditions

Compare media performance

Scale-up processes more effectively

How to Calculate OTRmax

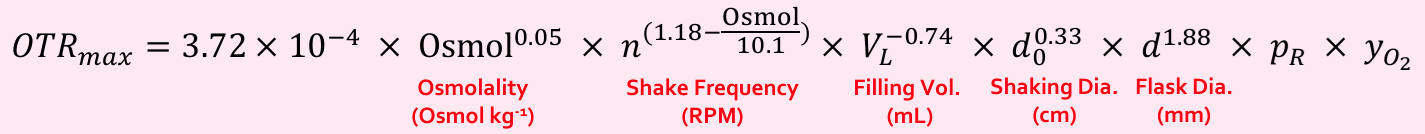

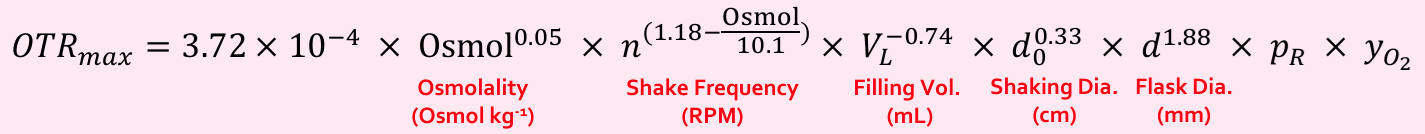

A widely accepted model proposed by Meier et al. (2016) provides a practical method to calculate OTRmax in shake flask systems. The model takes into account several key parameters:

Osmolality of the solution

Shaking frequency (rpm)

Culture volume

Orbital shaking diameter

Flask diameter

Ambient pressure (pR), typically 1 bar

Mole fraction of oxygen in air (yO2), typically 0.21

This equation allows researchers to estimate OTRmax under various culture conditions and media formulations.

Example: CHO Cell Cultivation

Let’s consider an example using Chinese Hamster Ovary (CHO) cells:

Under these conditions, the OTRmax = 10.5 mmol/L/h.

Now, if the user switches to ExpiCHO™ Stable Production Medium with a reduced volume of 30 mL and a lower osmolality (from 0.350 to 0.295 Osmol/kg), the OTRmax increases to 13.3 mmol/L/h. This illustrates how media composition and culture volume can significantly affect oxygen transfer capacity.

Simplify OTRmax Calculations

To assist users in optimizing their cultures, we provide a convenient OTRmax calculator mini-program on our website. Simply input your specific culture parameters to receive accurate estimates of OTRmax across various conditions.

English

English