1. Process Control and Monitoring

Advanced PLC Control System: Programmable logic controller (PLC) ensures stable, integrated management of pH, dissolved oxygen (DO), temperature, liquid level, and rotational speed, with graphical parameter display for real-time monitoring.

LCD Smart Touch Screen : Provides intuitive controls and visual alerts for seamless operation and monitoring (inferred from industry-standard bioreactor interfaces).

Why It Matters: Delivers precise, user-friendly control and real-time data visualization, optimizing microbial fermentation processes and ensuring reliability.

2. Temperature Regulation

Why It Matters: Maintains optimal thermal conditions, critical for microbial growth and consistent fermentation performance in laboratory-scale applications.

3. Dissolved Oxygen Management

Why It Matters: Ensures adequate oxygenation for microbial metabolism and productivity, enhancing fermentation yield and quality.

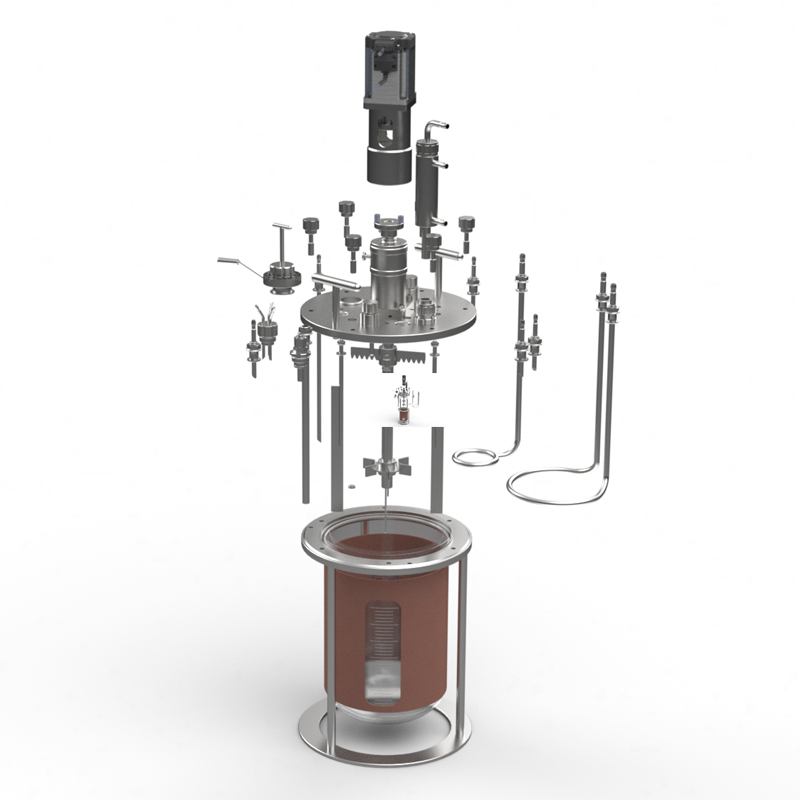

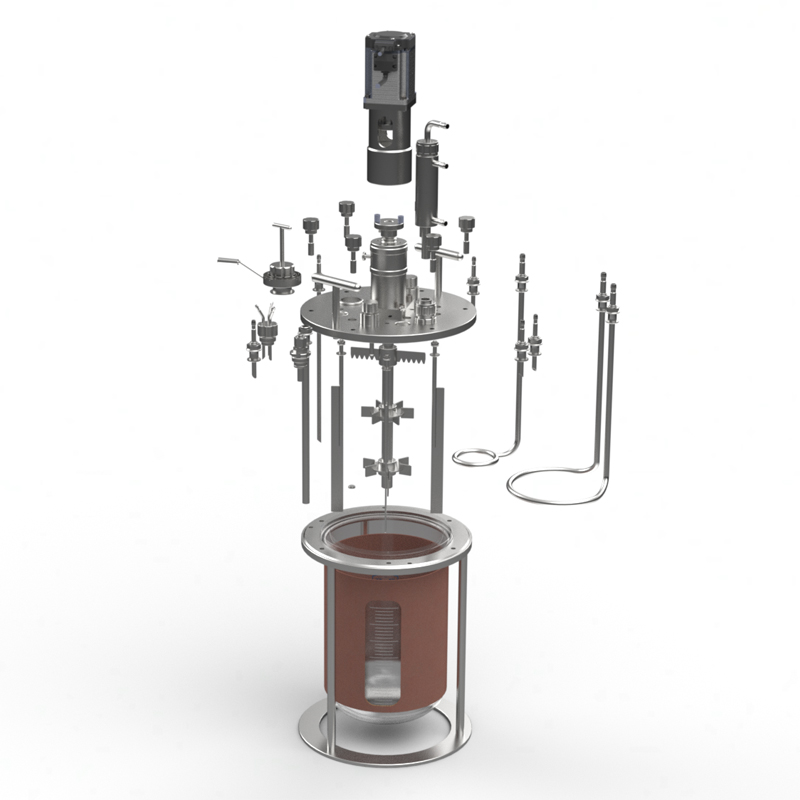

4. Agitation and Mixing

Why It Matters: Promotes consistent microbial growth and process efficiency, essential for strain screening and process optimization.

5. Feeding and Dosing Precision

Watson-Marlow Peristaltic Pumps: Three configurable pumps enable precise addition of acid/alkali, culture media, or defoaming agents, ensuring accurate pH, foam, and nutrient control.

Flexible Connection Interfaces: Includes pin feeding and flexible tubing (leather tube) interfaces for seamless integration with external systems.

Inoculation Port: Facilitates easy, contamination-free strain inoculation.

Why It Matters: Offers customizable dosing and feeding, enhancing process control and scalability for batch, fed-batch, and continuous fermentation.

6. Material and Hygiene

Corrosion-Resistant Construction: Specially treated 316L stainless steel (assumed standard) ensures durability, corrosion resistance, and compliance with laboratory hygiene standards.

Easy-to-Clean Design: Smooth, accessible stainless steel surfaces simplify cleaning and sterilization, maintaining a contamination-free environment.

Why It Matters: Guarantees long-term reliability and hygiene, critical for high-quality microbial fermentation and regulatory compliance.

7. Application Versatility

Flexible Fermentation Modes: Supports batch, fed-batch, and continuous chemostatic fermentation processes for microbial culturing.

High-Quality Components: Premium materials ensure consistent performance for process optimization, strain screening, and sample preparation.

Why It Matters: Accommodates diverse microbial fermentation needs, from research to small-scale production, enhancing application flexibility.

8. Ease of Installation and Operation

Why It Matters: Simplifies installation and operation, reducing setup time and enabling rapid deployment in laboratory environments.

English

English